Use Cases

Discover how our AI vision systems solve real-world challenges in automotive and manufacturing industries

Overview

IUNA AI's vision systems are deployed across a wide range of applications in the automotive and manufacturing industries. Our AI-powered solutions address critical quality control challenges, enabling automated inspection with unprecedented accuracy and efficiency.

From weld seam inspection to optical character recognition, our systems integrate seamlessly into existing production lines, providing immediate improvements in quality, reducing costs, and increasing operational efficiency.

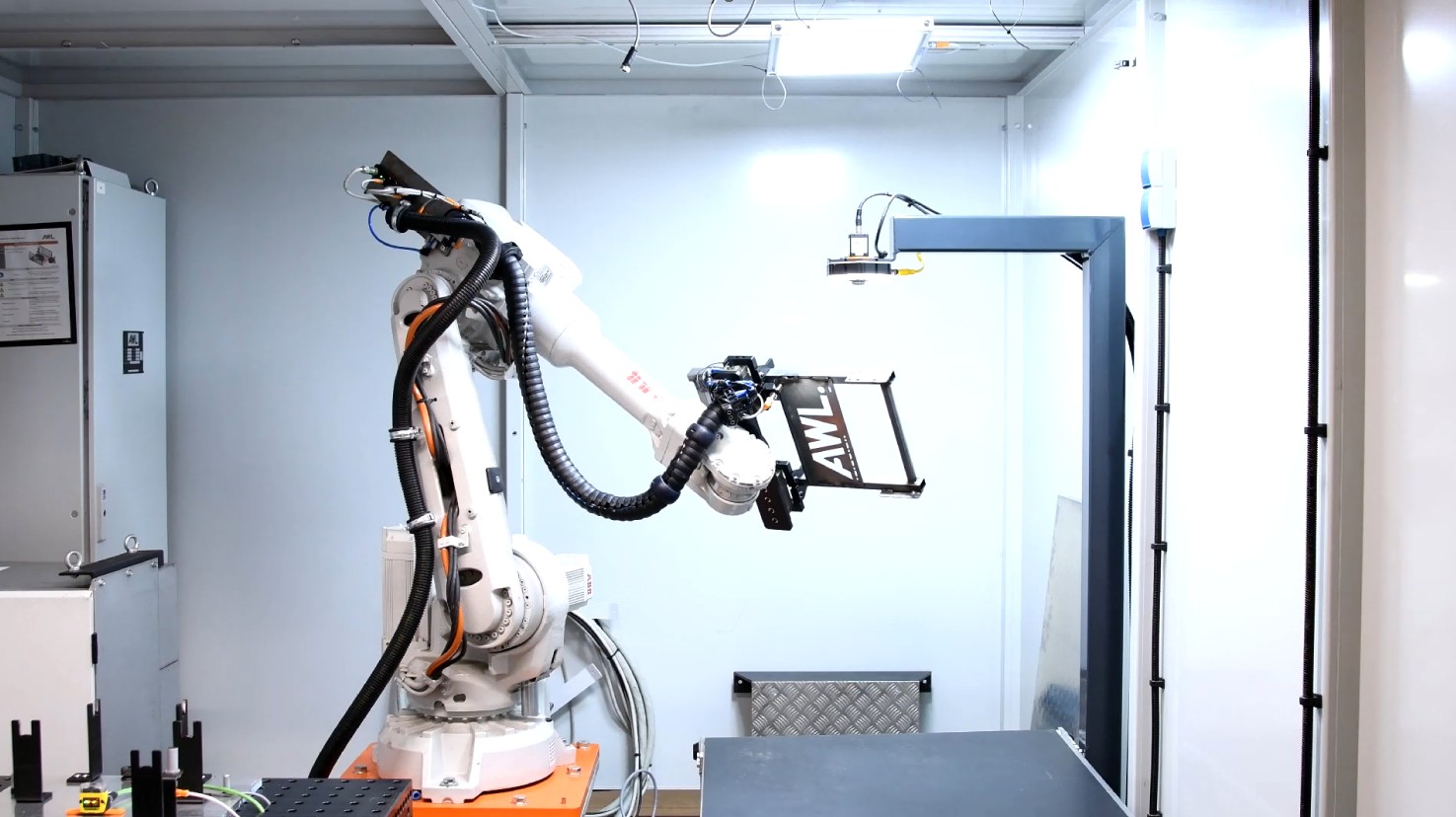

Weld Seam Inspection for Automotive Seating Structures

In this application, the IUNA AI Weld Inspector inspects all MAG weld seams of an automotive seating structure. The camera is statically mounted while a handling robot manages the component positioning, ensuring comprehensive inspection coverage.

- Statically mounted camera for consistent inspection quality

- Automated component handling via industrial robot

- Complete inspection of all MAG weld seams

- Real-time defect detection and classification

- Integrated with production line for seamless workflow

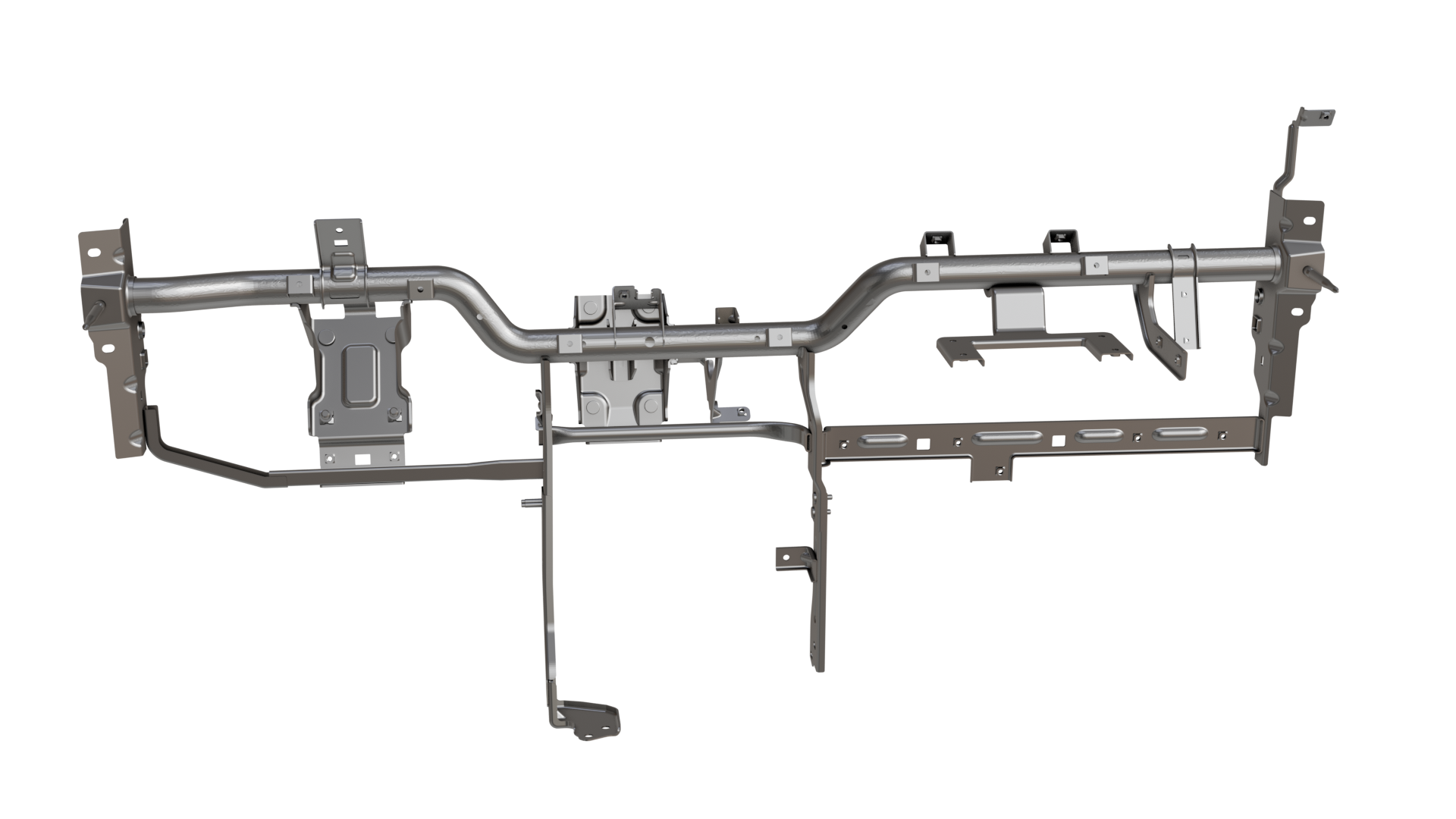

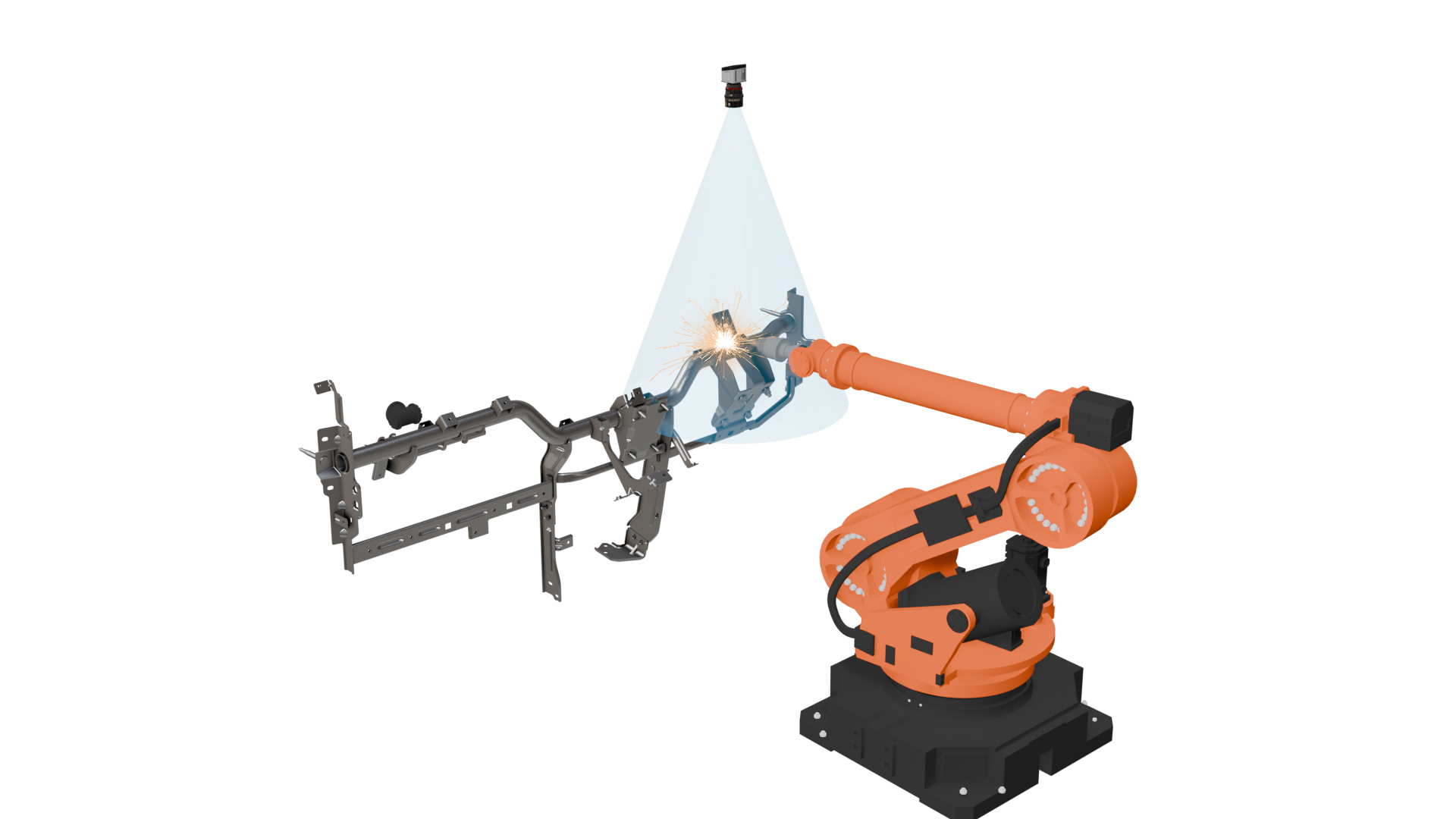

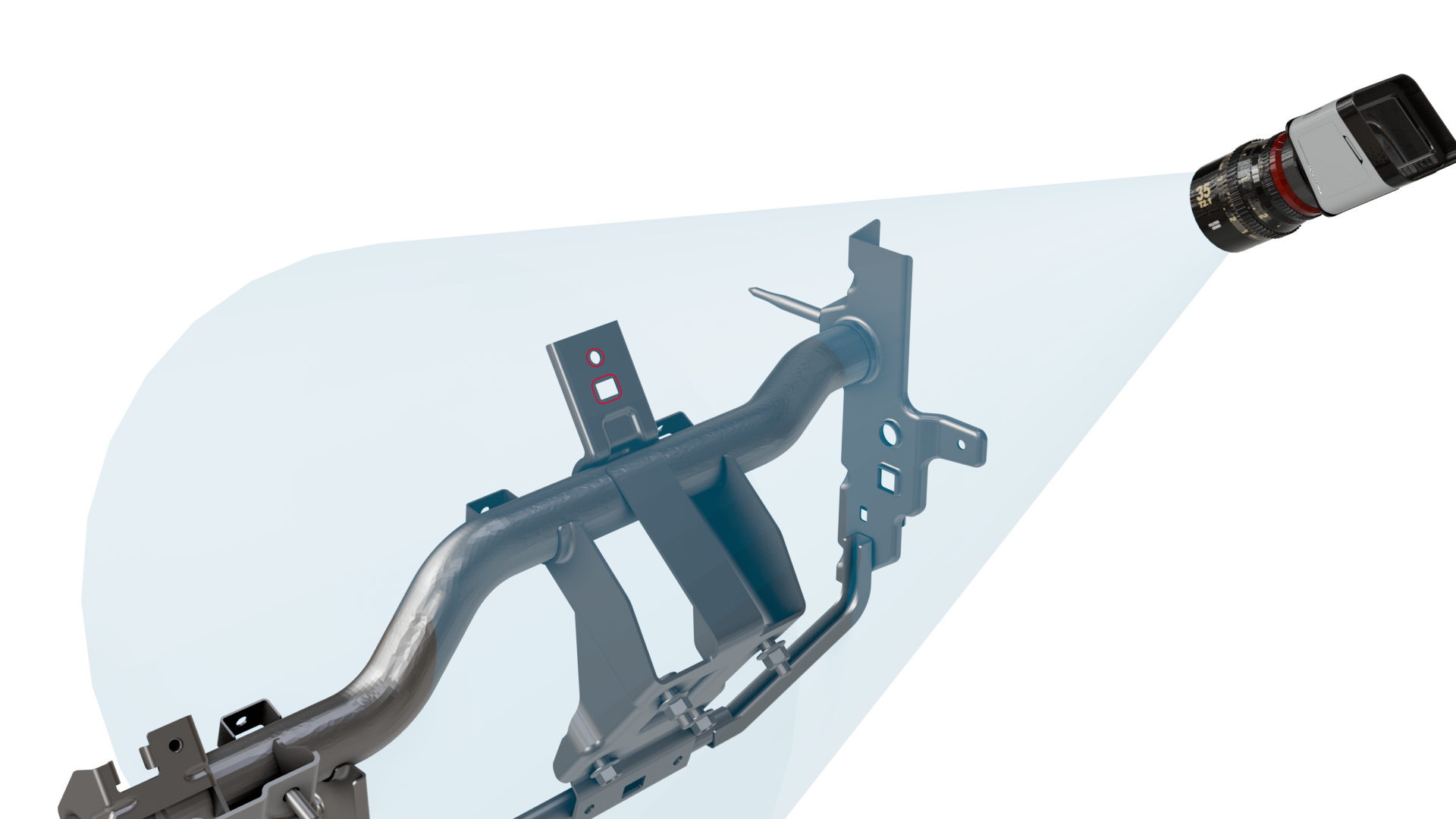

Weld Seam Detection for Cross Car Beams

Our weld seam detection system for Cross Car Beams (CCBs) offers flexible mounting options with cameras that can be mounted either statically or on an industrial robot. This enables fully automated inline weld seam inspection of CCBs with significantly faster cycle times compared to laser-based inspection systems.

- Flexible camera mounting: static or robot-mounted configurations

- Fully automated inline weld seam inspection

- Much faster cycle times than laser-based inspection systems

- Near real-time automated defect detection and classification

- Optimized for high-volume automotive production lines

Fully Automated Inspection of Weld Seams on Vehicle Bodies

The IUNA AI Weld Inspector is capable of inspecting the entire vehicle body for weld defects. Each individual weld seam can be inspected at different stations throughout the production process. The software checks for presence, length, and weld defects such as pores, cracks, burn-throughs, etc.

- Complete vehicle body inspection across multiple production stations

- Checks for weld presence, length, and defects (pores, cracks, burn-throughs, etc.)

- Cameras can be static or robot-mounted

- Supports both MIG and MAG welding processes

- Fully automated defect detection and classification

(Image Source: Audi AG)

Presence Check

Our presence check software verifies that all required components are correctly installed during the assembly process. Customers can conduct presence checks for features like nuts, bolts, studs, clips and holes during the same inspection cycle.

- Verifies presence of nuts, bolts, studs, clips, holes, and other components

- Prevents costly assembly errors and rework

- High-speed inspection suitable for production line integration

- Customizable for different component types and assembly configurations

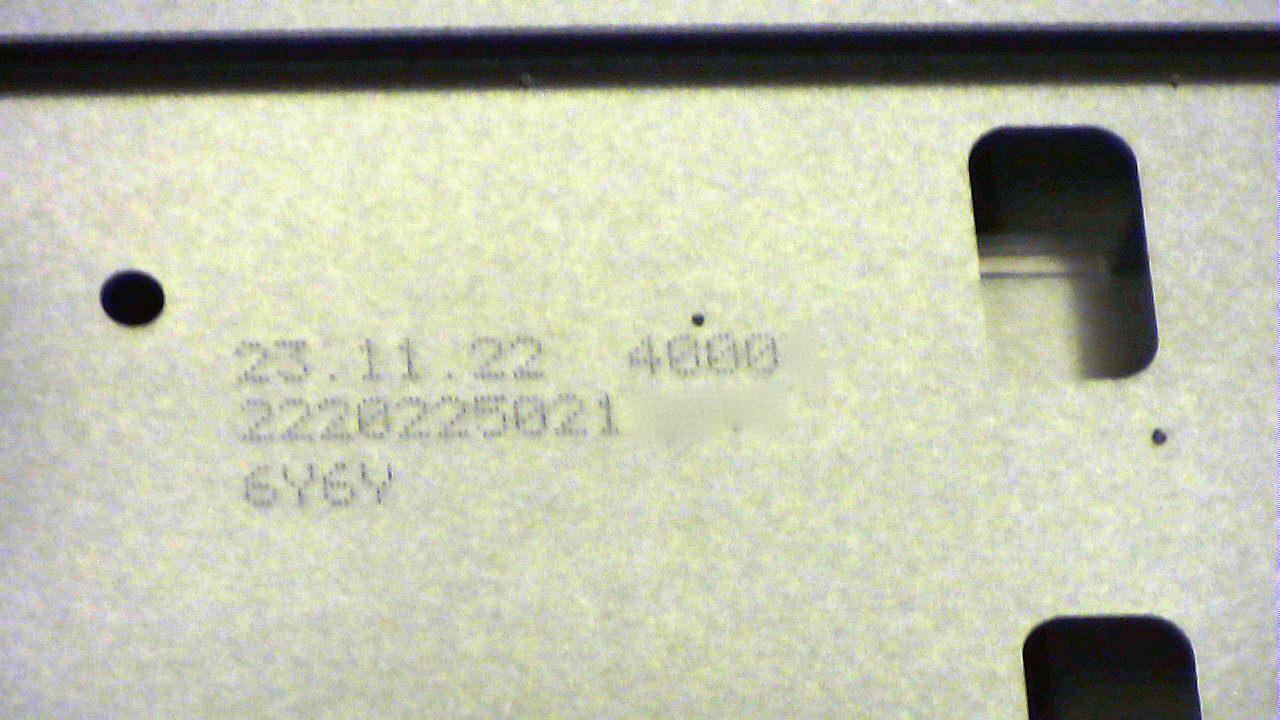

Optical Character Recognition (OCR)

Our OCR system reads and verifies text, codes, and serial numbers on components and assemblies. This ensures traceability throughout the manufacturing process and helps maintain quality control standards.

- Reads date codes, serial numbers, and part identifiers

- Ensures correct parts are used in assembly

- Maintains traceability throughout the manufacturing process

- Works with various marking methods including laser etching, dot peen, and printing

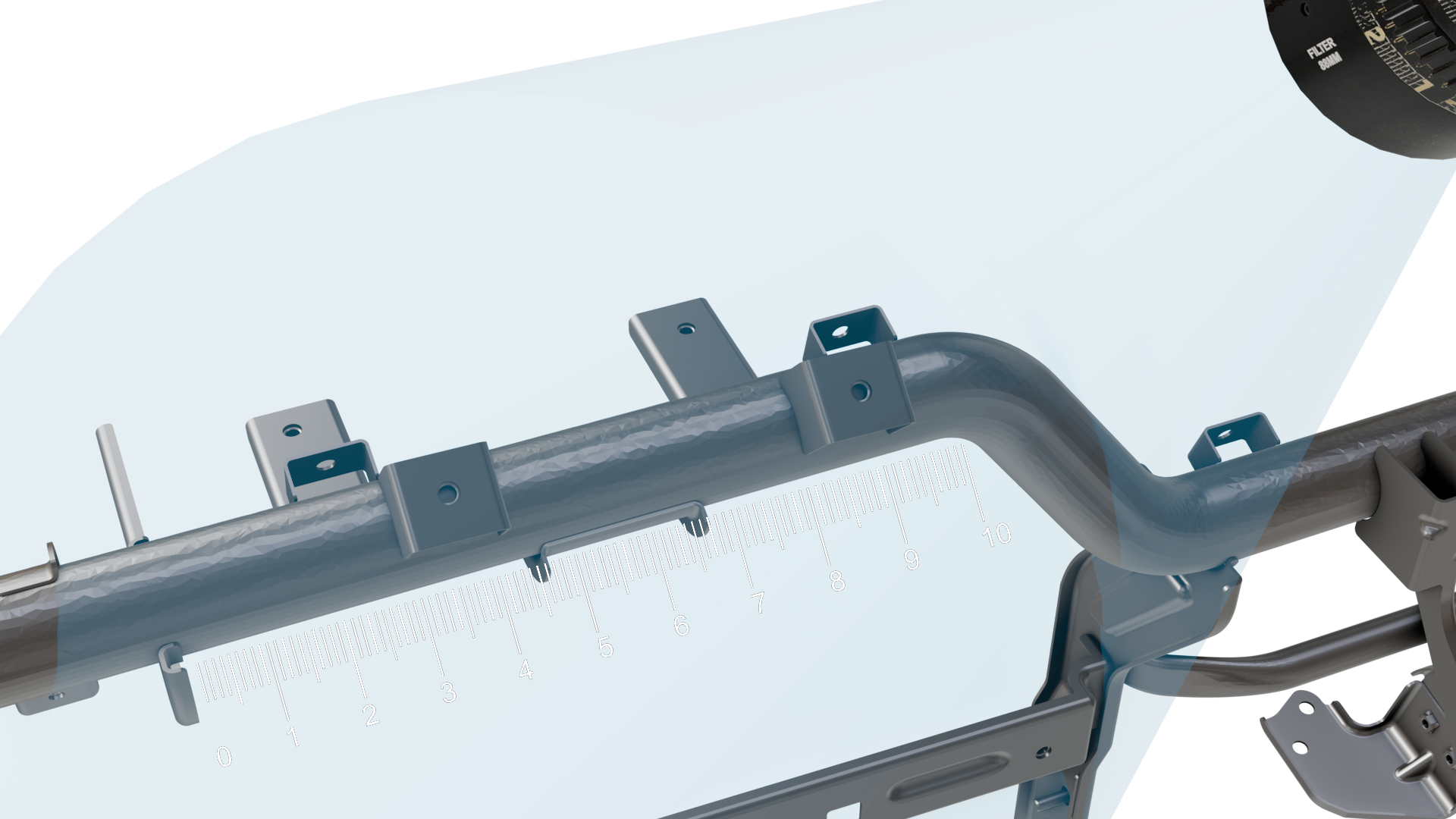

Dimensional Measurement

Our dimensional measurement system uses advanced computer vision to verify that components meet precise dimensional specifications. This ensures that parts fit together correctly during assembly and meet quality standards.

- Measures critical dimensions with sub-millimeter accuracy

- Inspects complex automotive components including body panels and structural elements

- Identifies deviations from CAD specifications

- Provides comprehensive measurement reports for quality control

Assembly Verification

Our assembly verification system ensures that complex assemblies are correctly put together. The system checks that all components are present, correctly positioned, and properly connected.

- Verifies correct assembly of complex components

- Checks for proper routing of cables and hoses

- Ensures correct positioning and orientation of parts

- Identifies missing or incorrectly installed components