News & Updates

Stay updated with the latest developments and achievements at IUNA AI

Basler Publishes Use Case Article About IUNA AI

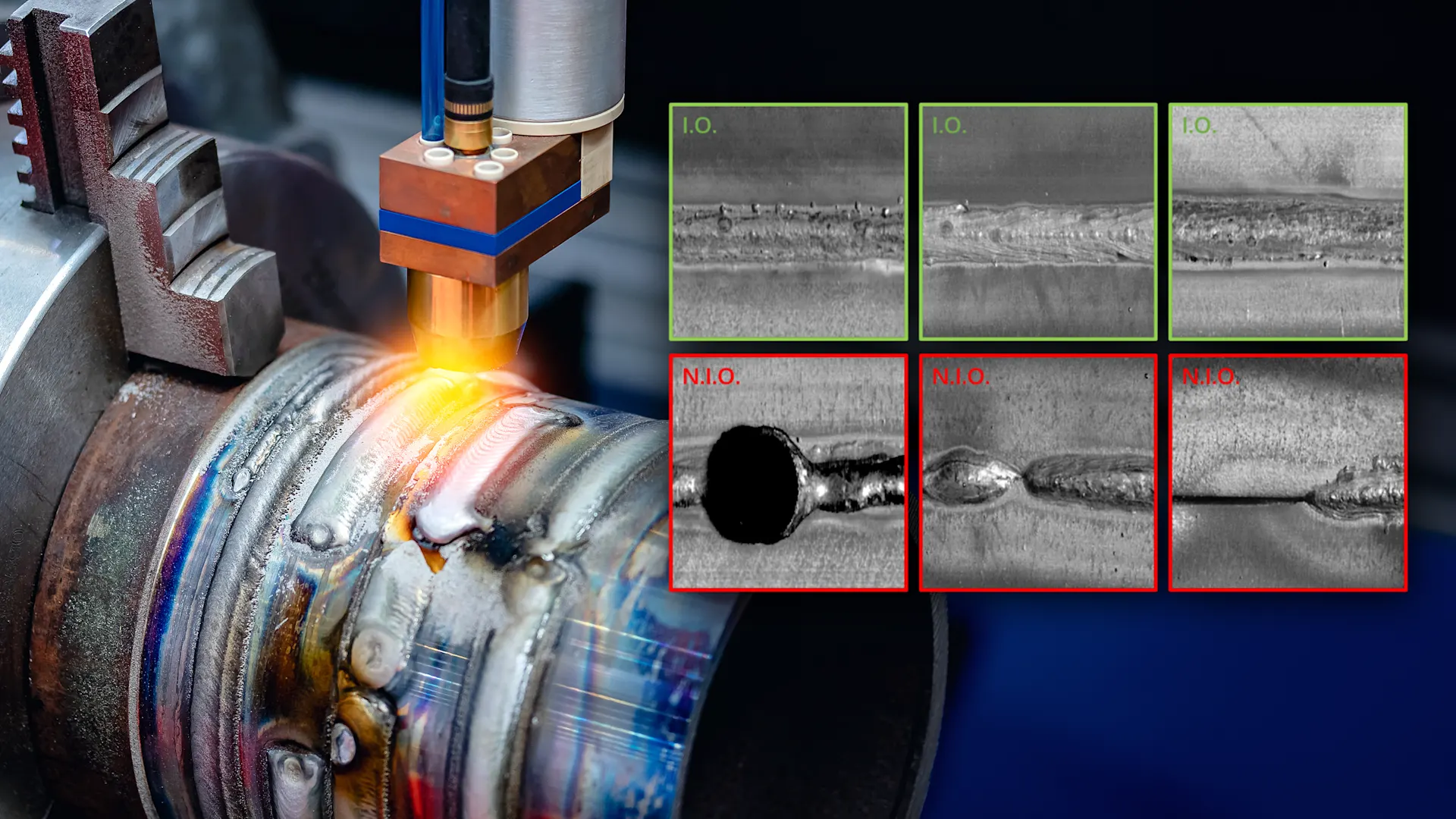

Basler, one of the world's leading manufacturers of industrial cameras, has published a detailed use case article about IUNA AI and our solutions for automated visual inspection in the automotive industry.

The article highlights how the IUNA Weld Inspector enables ISO-compliant weld seam inspection and how our AI-based systems automate visual inspection in body-in-white manufacturing. The collaboration between IUNA AI and Basler demonstrates how cutting-edge industrial imaging hardware combined with intelligent AI software delivers reliable quality assurance in demanding production environments.

"With Basler's high-performance industrial cameras and IUNA AI's intelligent software, we enable manufacturers to achieve 100% automated visual inspection compliant with international welding standards like ISO 5817."

New Update to Our IUNA Label Toolkit: How We Train AI Models in Minutes Instead of Days

Our self-developed IUNA Label Toolkit has received a new update! Since 2021, we have been continuously using and optimizing this internal tool to constantly improve our labeling pipeline and make it even more efficient.

Why are the IUNA Weld Inspector and Assembly Inspector ready for deployment so quickly? Because we have eliminated AI's biggest bottleneck: Manual labeling.

In this video, we reveal our internal "secret sauce": With the latest version of our Label Toolkit and Text-to-Mask technology, we train our models for your components in minutes instead of days. See for yourself how we detect weld seams using simple text commands.

By leveraging Vision Foundation Models and our continuously evolving IUNA Label Toolkit, we drastically reduce the commissioning time at your facility.

Want to know how quickly we can automate the inspection of your components?

Request a Feasibility Check NowIUNA AI at SCHWEISSEN & SCHNEIDEN 2025 in Essen

This year's SCHWEISSEN & SCHNEIDEN trade fair in Essen was truly special for IUNA AI. We had the opportunity to showcase the future of weld seam inspection live, and the response was overwhelming. Not only companies from the automotive sector stopped by, but also many other industries eager to explore how AI-powered inspection can enhance their quality processes.

Highlights from the Fair

Live Demo of Our Weld Seam Scanner: Visitors experienced real-time AI weld inspection firsthand, seeing how our technology moves beyond manual checks toward faster, more consistent quality control. The interactive demonstrations allowed attendees to see the system detect and classify weld defects in real-time, showcasing the practical benefits of AI-powered inspection.

AI Innovation in Practice: We demonstrated how computer vision and deep learning can be transformed into robust, practical tools for production environments. Our system's ability to detect defects according to international standards like ISO 5817, ISO 10042, and ISO 6520-1 impressed many visitors who are looking for reliable, automated quality assurance solutions.

Inspiring Conversations: The discussions with partners, customers, and new contacts were incredibly valuable. We connected with companies from various industries including automotive, manufacturing, metal fabrication, and construction, all interested in leveraging AI for quality control. These conversations have already led to several follow-up meetings and potential partnerships.

Partnership with AWL

We would like to extend a big thank you to everyone who visited us at our joint booth with AWL. The collaboration between IUNA AI's intelligent software solutions and AWL's expertise in smart robotic automation creates a powerful combination for the future of industrial quality control.

The journey of bringing deep learning-based weld inspection to production lines has just begun, and we're excited for what's next. The positive feedback and interest from the fair confirm that the industry is ready for AI-powered quality assurance, and we're proud to be at the forefront of this transformation.

IUNA AI featured in inVISION Magazine

We are pleased to announce that our company IUNA AI has been mentioned in the trade magazine inVISION News in the article "Weld Seam Inspection". The article presents our Weld Seam Vision System, which was specially developed for the automated inspection of MIG/MAG weld seams - for both manual and robot-assisted welding processes.

Our system provides comprehensive quality assurance by detecting weld seam defects in real-time, ensuring compliance with international standards including ISO 5817, ISO 10042, and ISO 6520-1. This recognition in a leading industry publication underscores our commitment to innovation in industrial quality control.

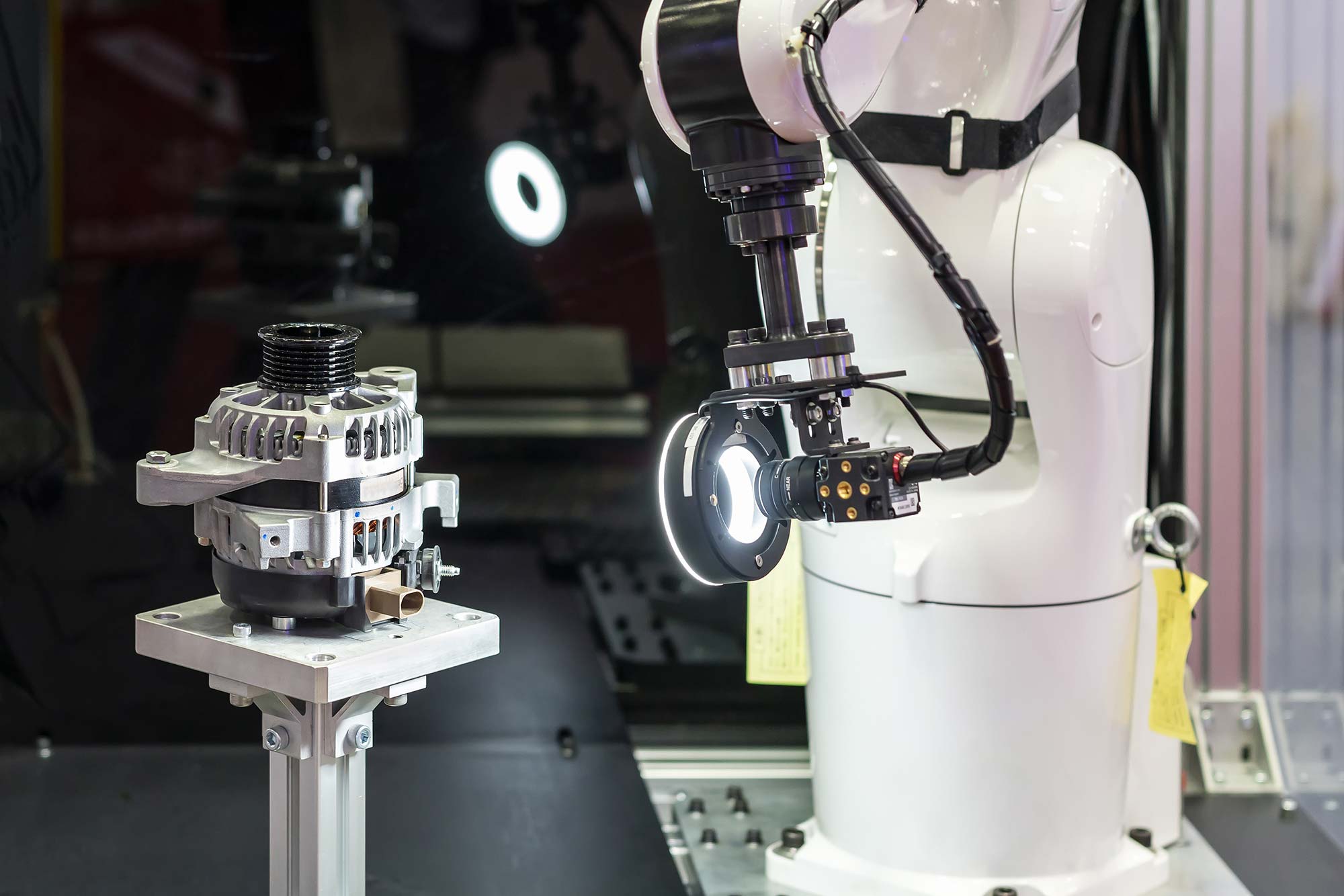

Valve cap recognition: IUNA supports wheel and tire assembly for OEMs

For our customers, checking the correct wheel/tyre combinations before delivery to the vehicle manufacturer is a major challenge. Due to the increasing diversification and individualization of tires, rims and valve caps, the requirements for precision and accuracy in tire assembly have risen sharply in recent years.

Thanks to the IUNA Assembly Inspector, it is now possible to automate this inspection process. The IUNA Assembly Inspector compares the color and shape of the valve cap and the valve on the image and compares this information with the target value from the database. This use of industrial computer vision and AI technology avoids errors and returns even before delivery.

Further development of the IUNA Auto Scanner for use in the final assembly (finish)

We are proud to announce the latest development of our IUNA Auto Scanner. The Auto Scanner can now also be used in the finishing process and accurately detects paint defects, dents, dings and other surface defects. This enhancement enables vehicle manufacturers to further improve the quality of their products and increase the efficiency of the final inspection.

The system uses advanced computer vision and AI algorithms to identify even subtle imperfections that might be missed by human inspectors. Our collaboration with Audi has been instrumental in refining this technology for high-end automotive applications.

Auto Scanner v3 / Body Shop

The third version of our Auto Scanner was expanded with "anomaly detection" functionality. The system not only detects predefined defects, but is also able to check the entire vehicle surface for anomalies. Anomalies are defects for which little to no historical image data is available. This means that even rare defects that would otherwise only be detected by humans can be captured fully automatically. This achieved complete automation of the inspection process in Audi's body shop and replaced manual visual inspection.

Release IUNA AI Inspector

Based on the know-how from the Auto Scanner, the IUNA AI Inspector was developed in September 2021. With the AI Inspector, we have developed a modular and easy-to-use AI image processing system that can be integrated inline. Combined with the right software application, we are flexible to solve a wide range of tasks in industrial manufacturing.

Auto Scanner v2 / Body Shop

In March, the second version of the IUNA Auto Scanner was completed. The system checks standard points on the vehicle body for surface geometry defects. These include waviness, dents, sheet metal irregularities and other defects that predominantly occur in the body shop department. In addition, the data helps the respective department to identify process-related errors or errors from suppliers.

Iuna.ai becomes development partner of Audi AG

In September 2020, iuna.ai became an official development partner of VW. The goal of the development cooperation was to further develop the IUNA Auto Scanner v1 in the body shop of the Audi R8 for fully autonomous identification of surface geometry defects on the body.

Auto Scanner v1 / Surface defect detection

In March 2020, the first version of the Auto Scanner was completed as part of the research project of the University of Stuttgart's Machine Learning group and Audi. This provided the proof of concept of an AI-based detection of surface damage on vehicles on the assembly line.

Press Article / IUNA AI x Audi

The current article in Heilbronner Stimme describes how Audi wants to drive change in production in the future and how we at IUNA AI are helping to shape this change. Our goal has always been to bring AI technology to today's manufacturing as easily and quickly as possible. We have already implemented exactly this for Audi. Further projects with Audi are in the planning phase.

Research project / Universität Stuttgart x Audi AG

The idea for an AI-based image data analysis came from a cooperation between the university group for Machine Learning at the University of Stuttgart and Audi AG in Neckarsulm. The goal of the research project was to deliver proof of concept of an AI-based autonomous quality assurance of vehicles on the assembly line. The university group was initiated and led by Jan Nabatian in 2019.