IUNA Weld Inspector

The Turnkey AI System for Optical Weld Inspection

Complete solution combining industrial imaging hardware and AI software to automate manual visual inspection.

Ensure the highest weld quality – based on international standards

Our system enables the visual inspection of weld seams in accordance with globally recognized welding standards. Click on each standard to learn more.

These standards ensure an objective, repeatable, and traceable assessment of weld quality across all production batches.

Intelligent Weld Seam Analysis

Our software combines deep learning-based AI models with rule-based algorithms, enabling precise detection of defects and accurate measurement of weld seam dimensions in millimeters.

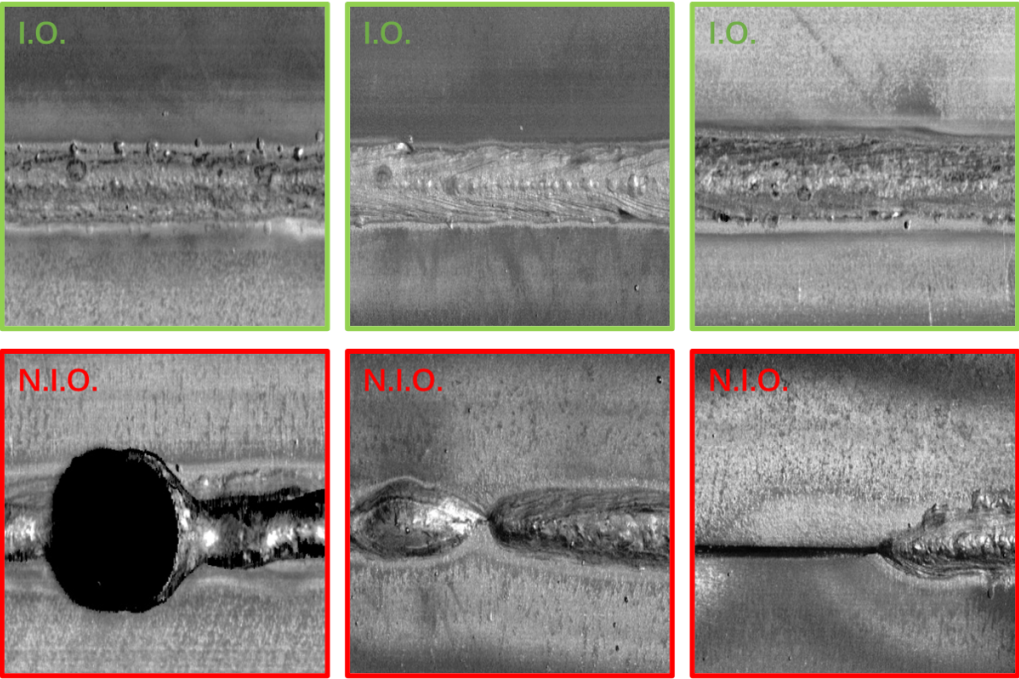

Automated Defect Detection

Automatic classification of weld seams as OK or NOT OK based on trained AI models that detect:

- Cracks, pores and blowholes

- Burn-through and spatter

- Asymmetry and geometric deviations

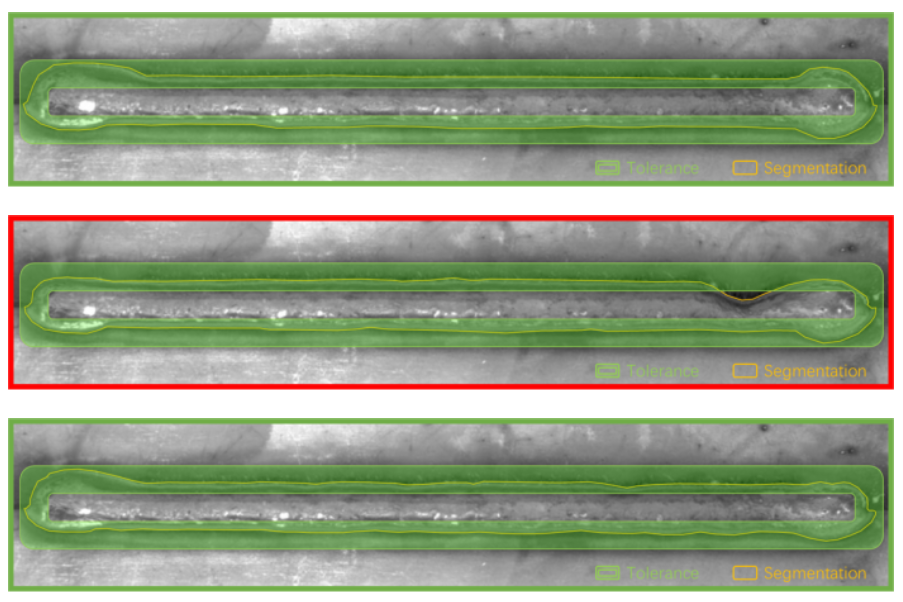

Tolerance & Segmentation Analysis

Rule-based algorithms verify weld seam position and dimensions against predefined tolerance ranges:

- Precise position verification

- Automatic tolerance range checking

- AI-powered segmentation

Weld Seam Dimensions in Millimeters

The hybrid approach of deep learning and rule-based algorithms enables precise measurement of weld seam length and width directly in millimeters. We can also measure directly at the component edge, ensuring the seam is symmetrical to the edge and verifying proper bonding. This provides accurate dimensional data for quality documentation and process optimization.

Modular design for maximum flexibility

Our complete turnkey system includes all hardware and software components for reliable weld seam inspection

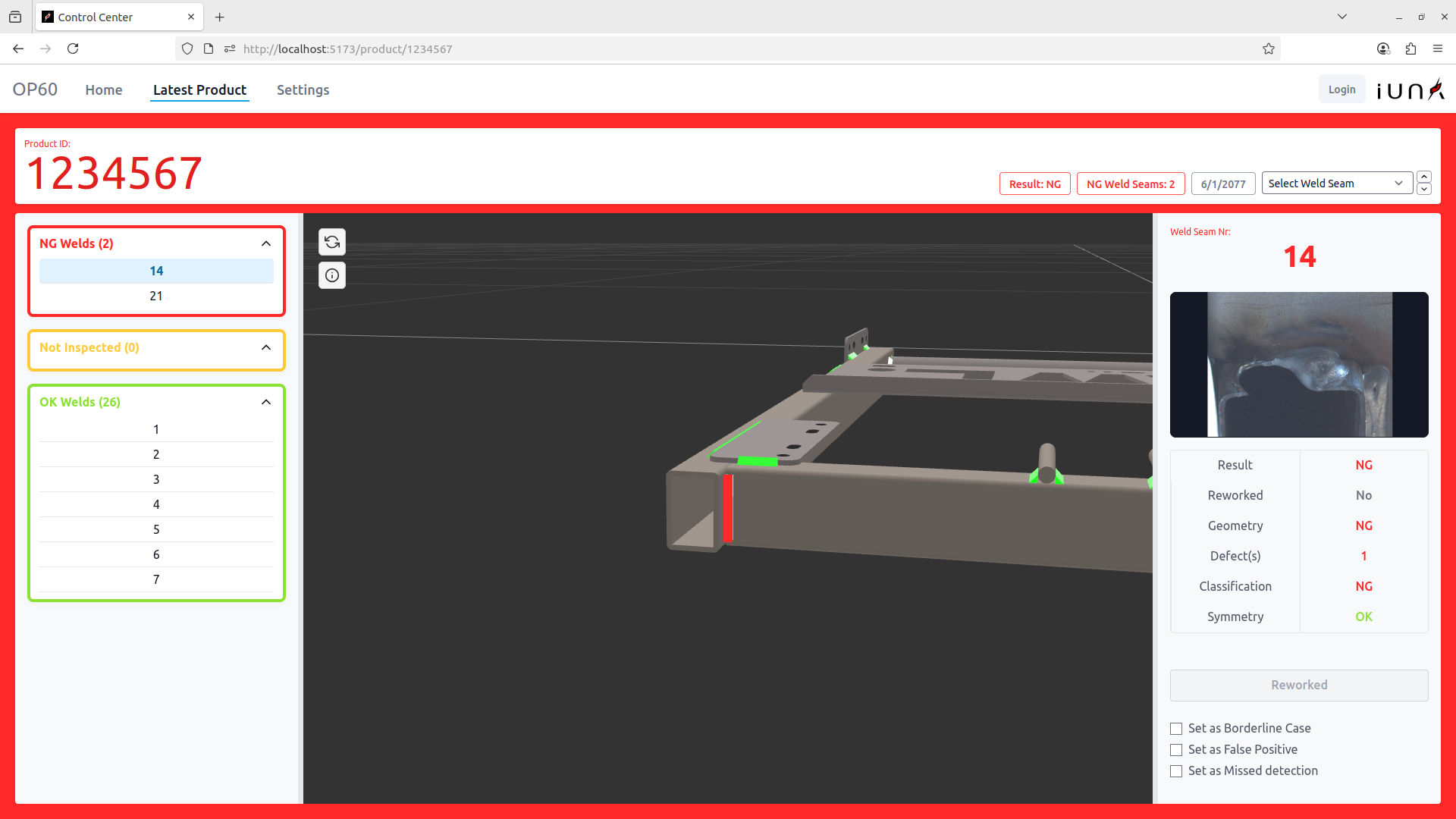

Intuitive User Interface with 3D Visualization

The user interface is hosted directly on the IUNA AI Server and can be accessed via any web browser from any PC with network connection to the server. No additional software installation required.

Interactive 3D Viewer

Rework operators can see at a glance which weld seam on the product requires rework - highlighted in red for NG (not good) and green for OK.

Real-time Results

Instant visualization of inspection results with detailed defect information and classification.

Browser-Based Access

Access from any networked device - no client software installation needed.

Industrial Camera

- High-resolution industrial cameras

- Including lenses and mounting

IUNA AI Server

- AI inference for image processing

- Available in 19″ rack housing

PLC

- PROFINET Simatic or EtherNet/IP

- Seamless line integration

Vision Light

- Industrial LED lighting

- Optimal weld seam visibility

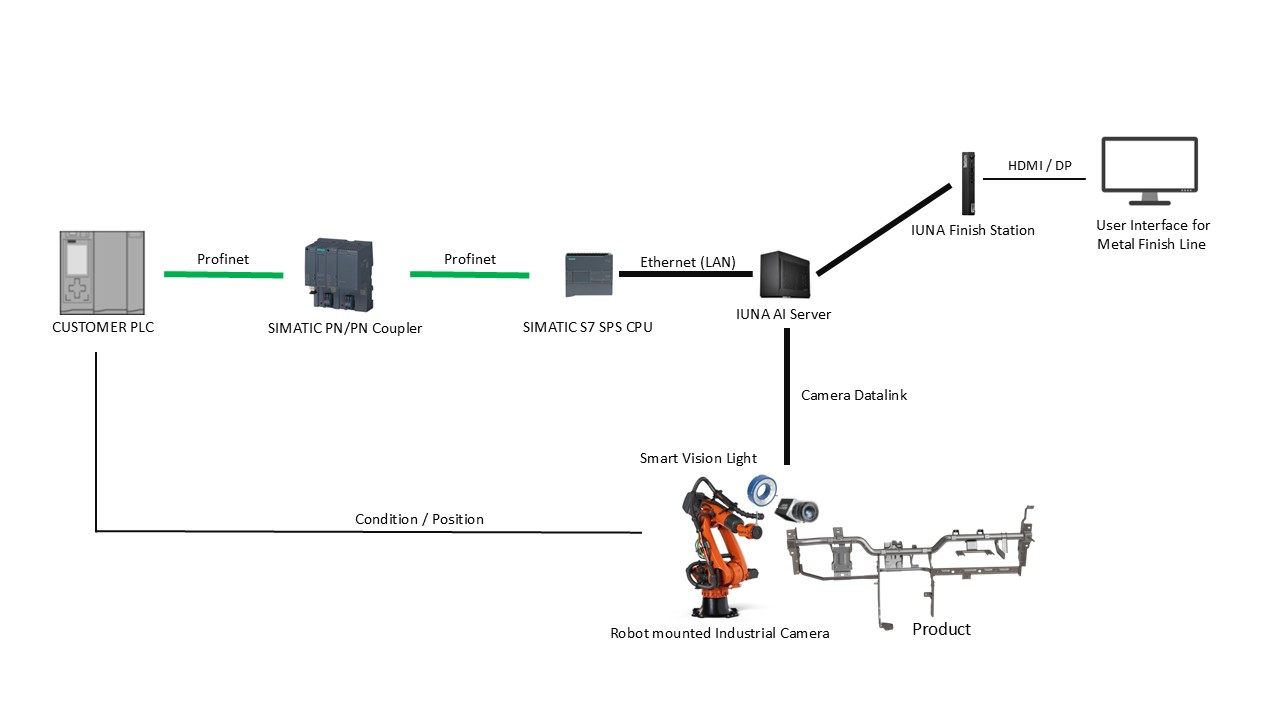

Flexible System Integration Options

The IUNA AI Weld Inspector can be easily integrated into your existing production environment via the included PLC. Choose from three flexible camera configuration options to match your specific production requirements.

1. Robot-Mounted Industrial Camera

The industrial camera is mounted on the robot arm, allowing flexible inspection of stationary parts from multiple angles.

PLC Compatibility

The IUNA AI Weld Inspector supports industry-standard communication protocols:

- PROFINET Simatic PLCs

- EtherNet/IP Allen-Bradley PLCs

Robot Compatibility

Full support for all major industrial robot brands:

- KUKA

- FANUC

- ABB

- Yaskawa

Complete Turnkey Solution

We deliver the complete hardware package including industrial camera technology and accessories such as lenses and tripods, light sources, PLC, and if required, the enclosure (inspection cell). We also handle on-site commissioning, so you can integrate the complete ready-to-use system into your production without any prior knowledge.

Advantages of Automated Visual Weld Seam Inspection

See why leading manufacturers choose the IUNA AI Weld Inspector over laser-based and ultrasound systems

Image Capture in Less Than 0.5 Seconds

The AI Weld Inspector flies over the seam (or the part moves past the camera), and the result is available immediately. We don't slow down your production line - we keep pace with it.

vs. Laser-Based Systems

Significantly More Cost-Effective

No expensive 3D laser profile sensors required - just high-resolution industrial cameras

Much Faster Inspection

Extremely fast cycle times that don't slow down your production

Superior Detection for Low-Height Welds

Detects fine details where laser systems reach their limits

vs. Ultrasound Testing

100% Inline Inspection

We inspect every single part in cycle time - no offline sampling required

No Part Contamination

Non-contact inspection keeps your parts clean and ready for the next process

Low Maintenance

No coupling agents, no wear parts - reliable operation with minimal upkeep

One-Click Complete Reports

Our customers love the ability to generate complete inspection reports with a single click. See exactly which weld seams are causing problems, how many welds across how many products are defective on average, and track quality trends over time.

- Identify problematic welds instantly

- Average defect rates across products

- Historical trend analysis

- Export to PDF, CSV, or integrate via API

Drop-in Solution

Ready to integrate into any robot cell without extensive modifications

Real-Time Results

Operates in production cycle time with instant pass/fail decisions

Consistent Quality

Eliminates human error with objective, repeatable inspections

Our proven implementation process ensures a smooth integration

Our proven implementation process ensures a smooth integration of the IUNA AI Weld Inspector into your production environment:

Evaluation of Use Case

Contact us. Together, we will check your use case and the implementation options. After that we will select the required hardware components.

System Installation

We integrate all required hardware into your production process: industrial camera, IUNA AI Server, PLC, lighting system, and if necessary an inspection cell. We also install and configure our AI vision software.

AI Model Teaching & Configuration

The first image data is used to teach the AI inspection software. Even a small amount of images is sufficient for this.

Autonomous Inspection

From now on, the IUNA AI Weld Inspector takes over your inspection fully automatically. With the help of advanced AI vision models, you achieve consistent, objective quality control that is far superior to manual inspection.

Ready to automate your weld seam inspection?

Contact our team to schedule a personalized demonstration of the IUNA AI Weld Inspector.