IUNA Assembly Inspector

Automated visual inspection for your production

The intelligent camera system for your quality assurance

With the IUNA Assembly Inspector, we offer you a system that can be used flexibly in quality assurance. Each Assembly Inspector is individually configured for your manufacturing process. By optimally coordinating software and hardware, we maximize the reliability of the inspection.

For our Assembly Inspector, we combine high-resolution industrial cameras and customized AI models. This allows us to offer you automated testing with maximum precision.

Areas of Application

The IUNA Assembly Inspector offers versatile solutions for a wide range of quality assurance challenges in manufacturing

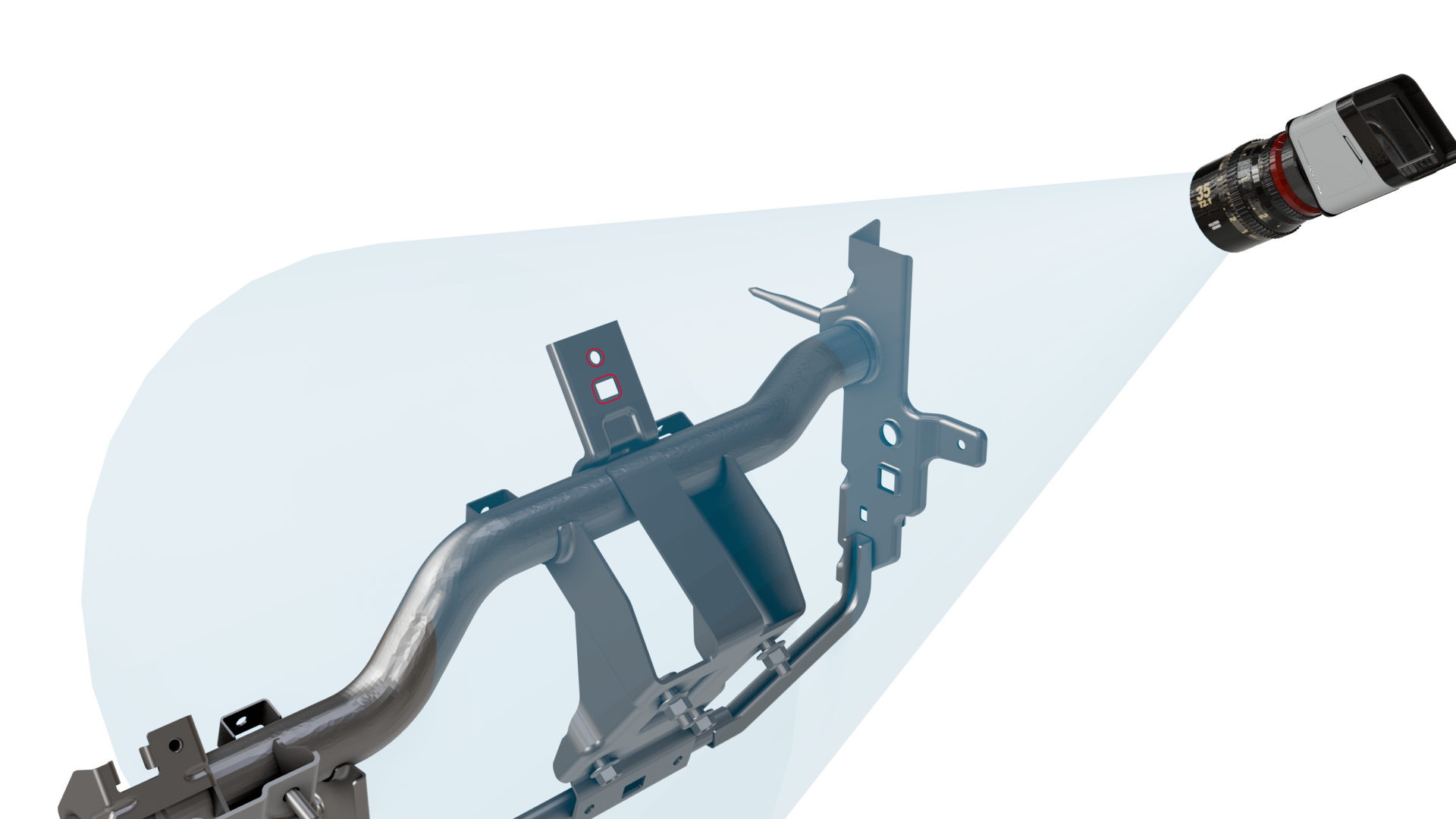

Presence Check

Our Assembly Inspector excels at verifying the presence of critical components in complex assemblies. The system can detect even small parts like nuts, bolts, clips, and connectors with high precision.

- Verification of nuts, bolts, studs, and clips

- Detection of missing or incorrectly installed components

- Inspection of multiple features in a single cycle

- Prevention of costly assembly errors and rework

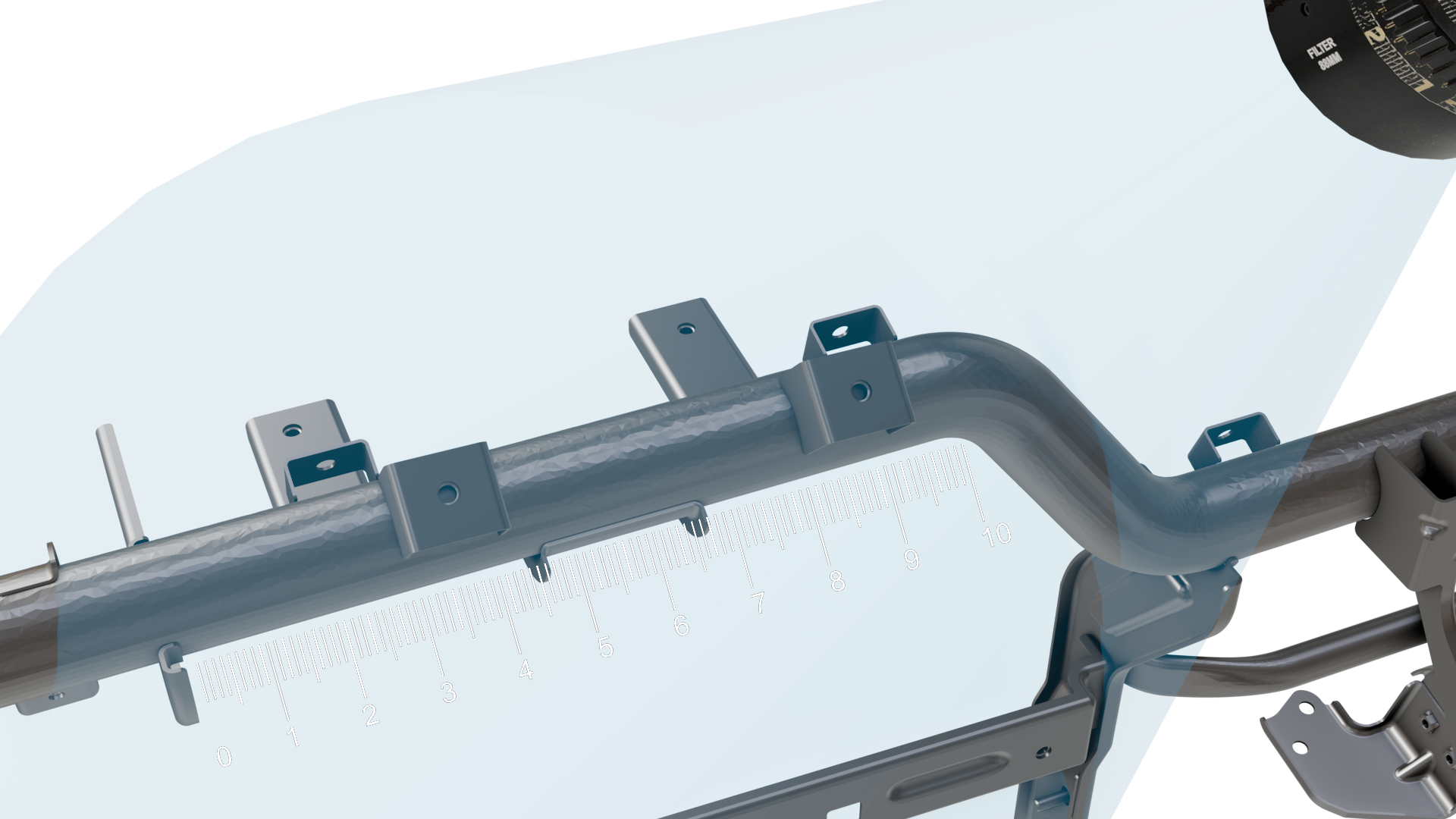

Dimensional Measurement

Our Assembly Inspector provides precise dimensional measurements of critical components, ensuring they meet exact specifications. The system can measure distances, angles, diameters, and other geometric parameters with sub-millimeter accuracy.

- Verification of dimensional and positional tolerances

- Measurement of hole spacing, angles, and gaps

- Comparison with CAD specifications

- Simultaneous measurement of multiple dimensions in-line

Optical Character Recognition (OCR)

Read and verify text, serial numbers, and labels on components. Our OCR system handles various fonts, sizes, and surfaces with high accuracy.

- Text and serial number recognition

- Support for various fonts and surfaces

- Label verification and quality control

Code Reading

The Assembly Inspector reliably reads and verifies QR codes, Datamatrix codes, and barcodes. This enables seamless traceability and automated identification of components throughout the production process.

- Reading of QR codes, Datamatrix codes, and barcodes

- Component traceability throughout production

- Verification of code readability and content

- Integration with MES and ERP systems

Modular design for maximum flexibility

Our complete turnkey system includes all hardware and software components for reliable visual inspection

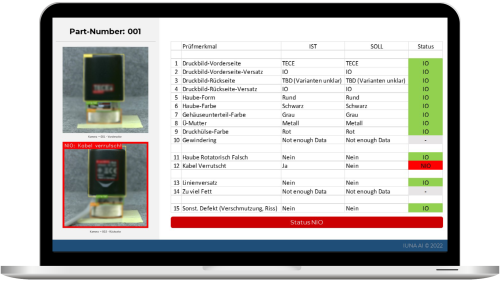

Intuitive User Interface

The user interface is hosted directly on the IUNA AI Server and can be accessed via any web browser from any PC with network connection to the server. No additional software installation required.

Real-time Visualization

Operators can see inspection results immediately with clear OK/NG status indicators.

Instant Results

Fast AI inference delivers inspection results with detailed defect information.

Browser-Based Access

Access from any networked device - no client software installation needed.

Industrial Camera

- High-resolution industrial cameras

- Including lenses and mounting

IUNA AI Server

- AI inference for image processing

- Available in 19″ rack housing

PLC

- PROFINET Simatic or EtherNet/IP

- Seamless line integration

Vision Light

- Industrial LED lighting

- Optimal component visibility

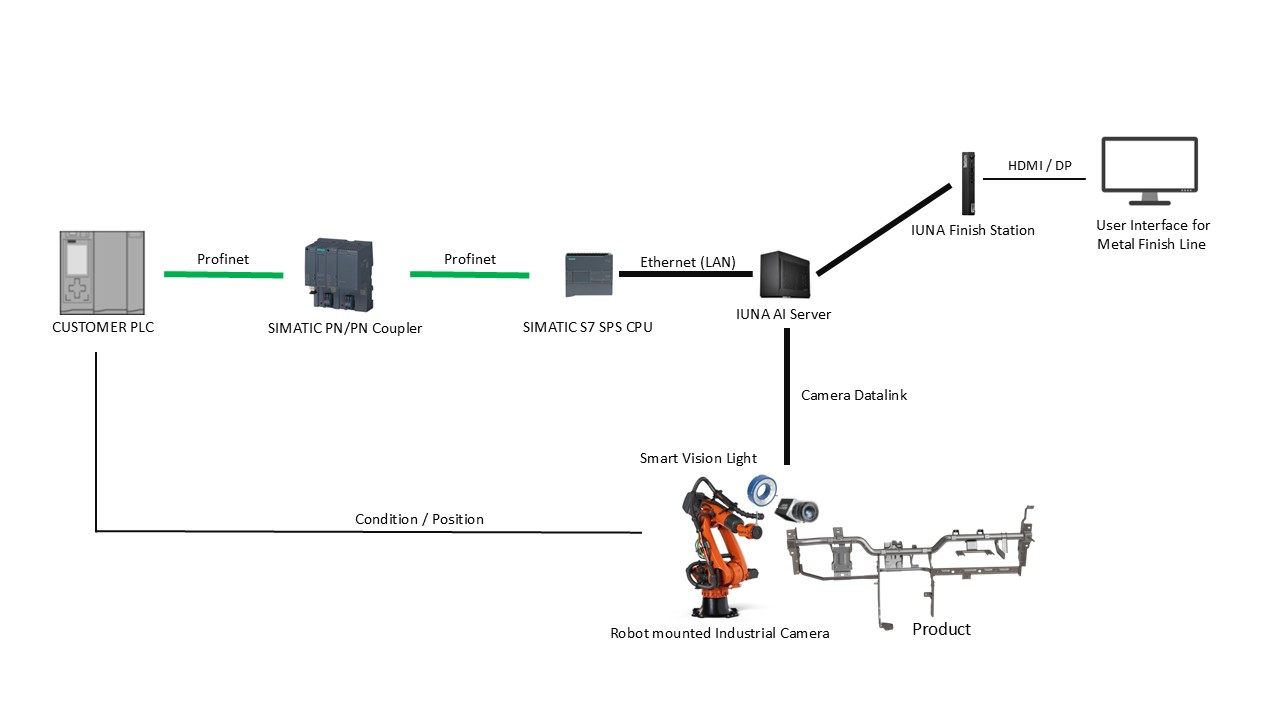

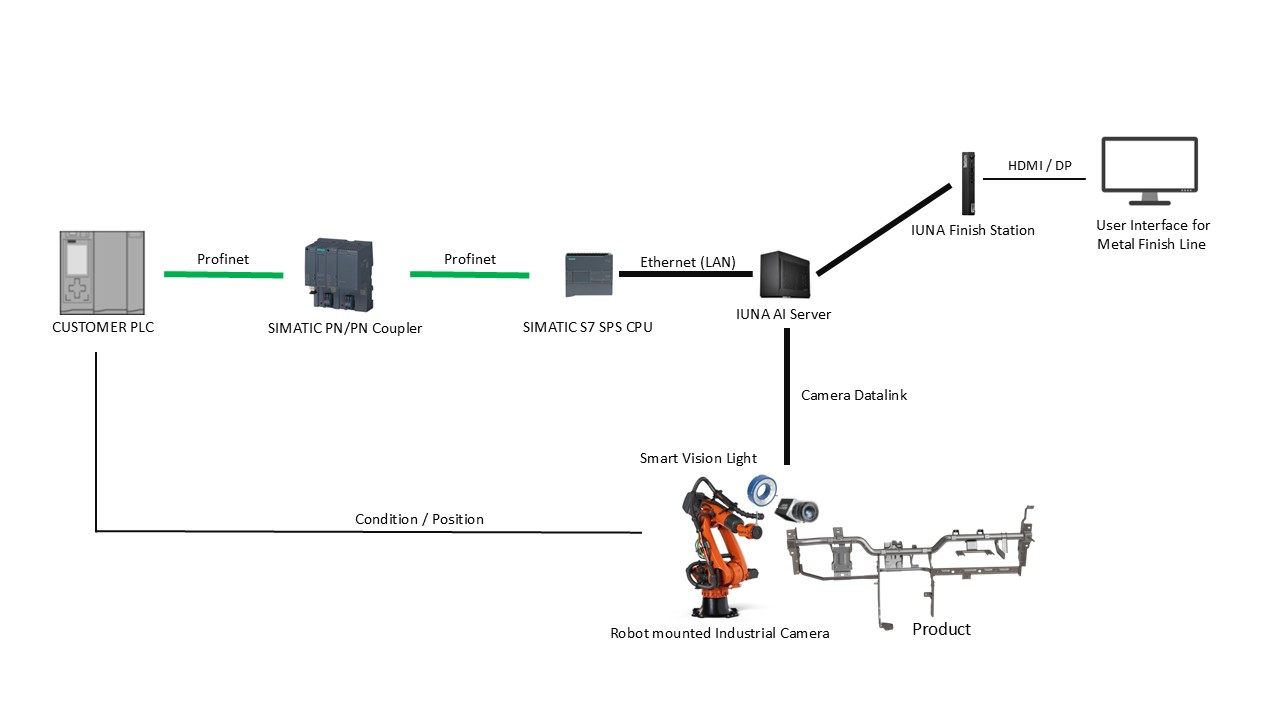

Flexible System Integration Options

The IUNA Assembly Inspector can be easily integrated into your existing production environment via the included PLC. Choose from three flexible camera configuration options to match your specific production requirements.

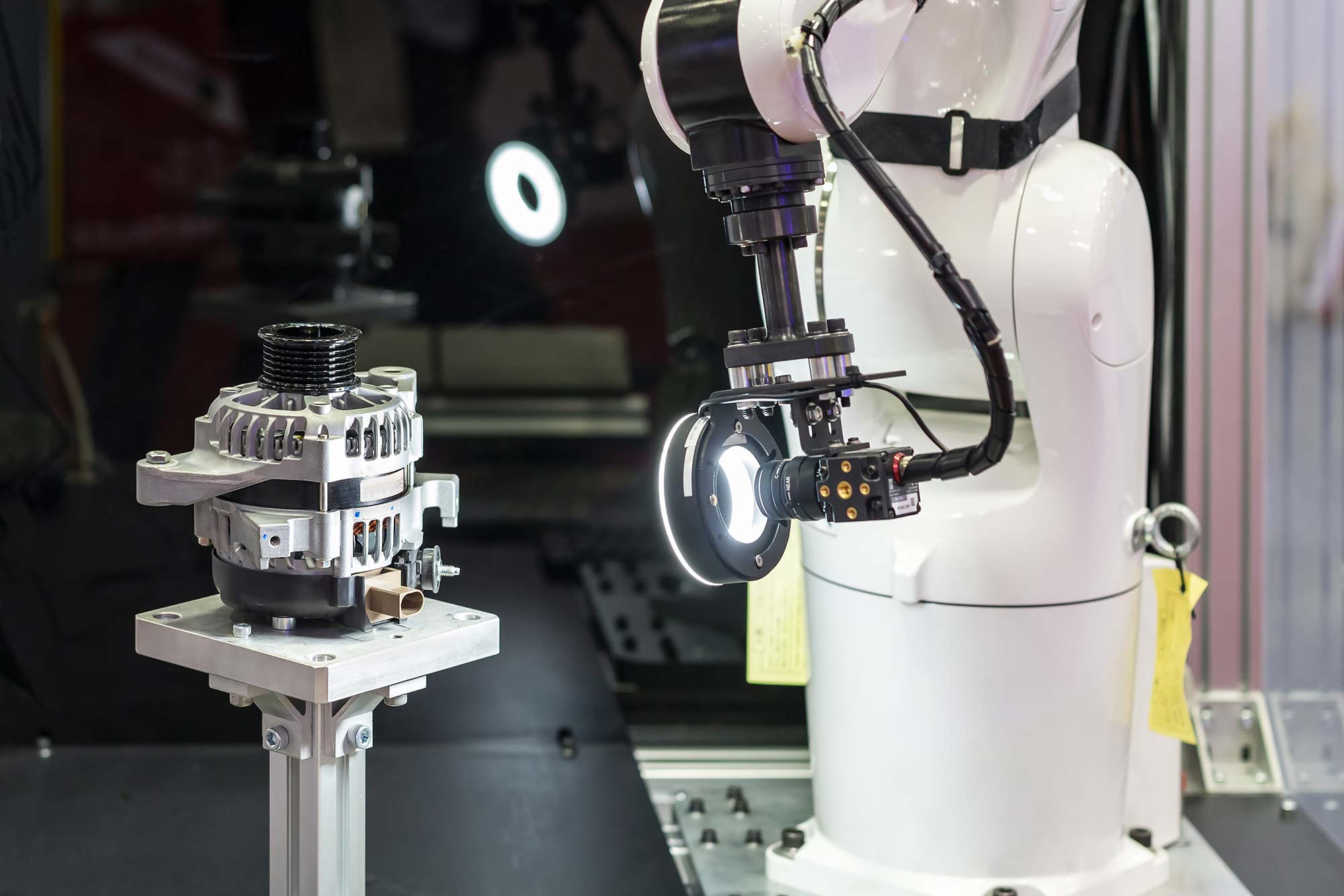

1. Robot-Mounted Industrial Camera

The industrial camera is mounted on the robot arm, allowing flexible inspection of stationary parts from multiple angles.

PLC Compatibility

The IUNA Assembly Inspector supports industry-standard communication protocols:

- PROFINET Simatic PLCs

- EtherNet/IP Allen-Bradley PLCs

Robot Compatibility

Full support for all major industrial robot brands:

- KUKA

- FANUC

- ABB

- Yaskawa

Complete Turnkey Solution

We deliver the complete hardware package including industrial camera technology and accessories such as lenses and tripods, light sources, PLC, and if required, the enclosure (inspection cell). We also handle on-site commissioning, so you can integrate the complete ready-to-use system into your production without any prior knowledge.

Advantages of the IUNA Assembly Inspector

The IUNA Assembly Inspector offers numerous advantages for your production

Maximum Precision

Our AI models are trained for highest precision and provide reliable inspection results.

Fast Integration

Our systems can be seamlessly integrated into existing production lines.

Reliable Results

Consistent quality control through objective AI-based inspection.

Cost Efficiency

With the Assembly Inspector you save working time and money. At the same time, costs are predictable and transparent.

Fast Cycle Times

Due to Multi-GPU processing the Assembly Inspector can process large amounts of data very fast and comply short cycle times.

Custom AI Models

Our AI models are individually trained and optimized for your specific requirements.

Our Implementation Process

Our proven implementation process ensures a smooth integration of the IUNA Assembly Inspector into your production environment

Use Case Assessment

We analyze your requirements and develop a customized solution concept.

System Installation

We install the complete hardware including industrial camera, IUNA AI Server, PLC, lighting technology, and if necessary an inspection cell at your site.

AI Model Teaching & Configuration

We train and configure the AI models specifically for your inspection task.

Autonomous Inspection

From now on, the Assembly Inspector takes over your inspection fully automatically. With the help of the user interface, you can track and evaluate results at any time.

Integration Options

Choose the integration option that best fits your production needs.

Robot-Mounted Industrial Camera

The industrial camera is mounted on the robot arm, allowing flexible inspection of stationary parts from multiple angles.