IUNA Weld Seam Scanner

Fully automatic visual inspection of weld seams

Ensure the highest weld quality – based on international standards

Our system enables the visual inspection of weld seams in accordance with globally recognized welding standards:

- ISO 5817: Defines quality levels and acceptance criteria for weld imperfections in steel, stainless steel, titanium, and nickel.

- ISO 10042: Applies specifically to aluminum welds and sets limits for acceptable deviations in aluminum arc welding.

- ISO 6520-1: Serves as the classification basis for all welding imperfections and defines the types and categories of weld seam irregularities.

These standards ensure an objective, repeatable, and traceable assessment of weld quality across all production batches.

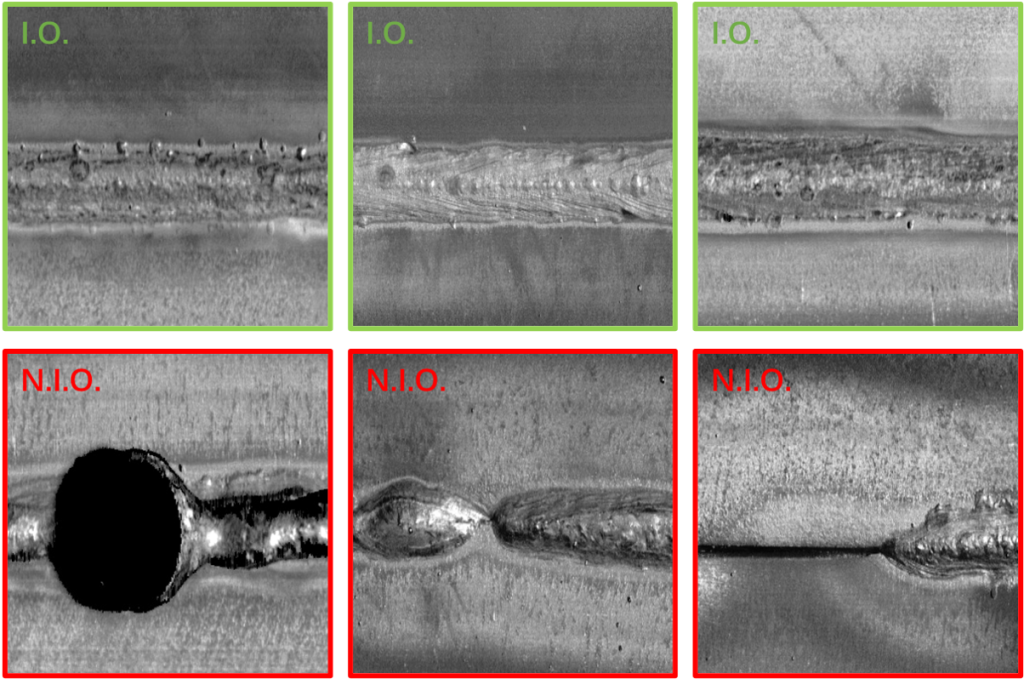

Weld Testing

With the IUNA Weld Seam Scanner you can automate various testing and inspection steps:

- Is the weld seam there?

- Is the weld seam within the predefined tolerance range?

- Automatic detection of irregularities in the weld seam

- Automatic detection of cracks, pores, open end crater blowholes, burn-through, spatter, excessive asymmetry in the fillet and other defects that can be expected in normal production

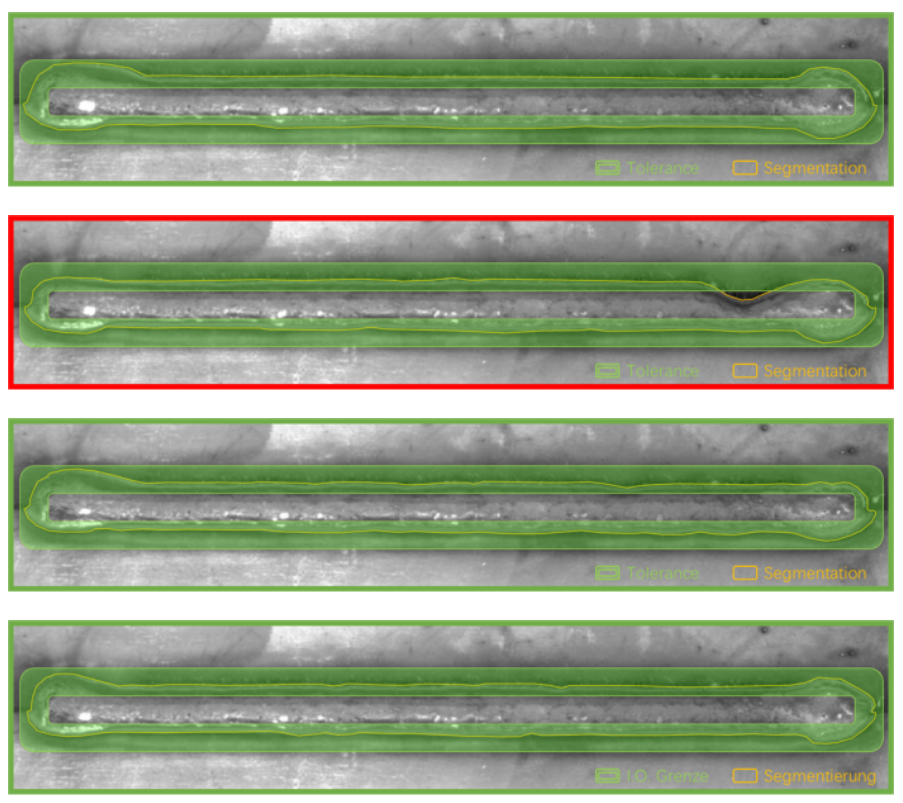

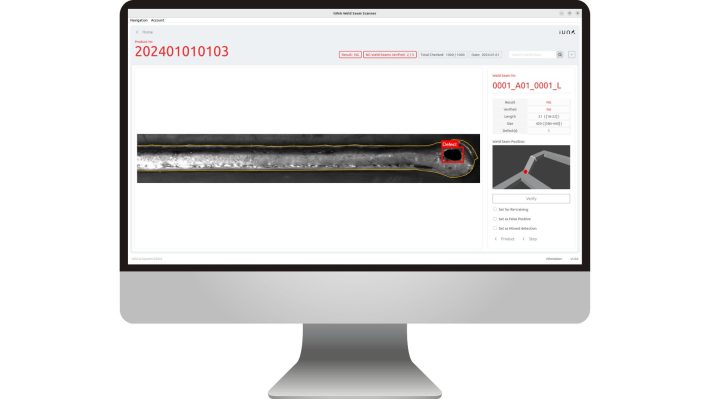

Precise AI Analysis

Our AI-powered system precisely analyzes each weld seam, identifying the tolerance range and performing detailed segmentation. The IUNA Weld Seam Scanner can detect even the smallest defects that might be invisible to the human eye.

The system automatically determines whether a weld seam is within the acceptable tolerance range and highlights any areas that require attention. This ensures consistent quality control and reduces the risk of defective parts reaching the next production stage.

- Precise tolerance measurement

- Advanced segmentation algorithms

- Real-time defect detection

Advantages of automated visual weld seam inspection

Cost-Effective Solution

The IUNA Weld Seam Scanner is particularly user-friendly and efficient, as it only requires a high-resolution industrial camera for inspection and not an expensive 3D laser sensor. This makes our system significantly more cost-effective compared to laser-based inspection systems.

Superior Detection Capabilities

Our system offers outstanding performance for weld seams with very low heights. Thanks to the high-resolution industrial camera, the IUNA Weld Seam Scanner can detect fine details and small irregularities where laser-based systems often reach their limits.

Consistent Quality Control

Automated inspection eliminates human error and ensures consistent, objective evaluation of weld seams, increasing product quality and safety. This is particularly important in safety-critical sectors such as the automotive and aerospace industries.

Seamless Integration

Integration into existing production lines is straightforward, increasing overall production efficiency. The IUNA Weld Seam Scanner offers a reliable, economical and user-friendly solution for modern quality control requirements.

Modular design for maximum flexibility

Our system consists of three main components that work together seamlessly

Industry Camera

- One or more high-resolution industrial cameras

- Suitable for the inspection of manual and automatically welded seams

- Can be integrated into existing production

Vision Software

- Easy-to-use user interface

- Real-time visualization

- AI-supported

AI Station

- AI inference server designed for image processing (also available in 19″ housing)

- Compatible with common interfaces (PROFINET, ProfiBus, digital IOs,...)

- Robust and reliable

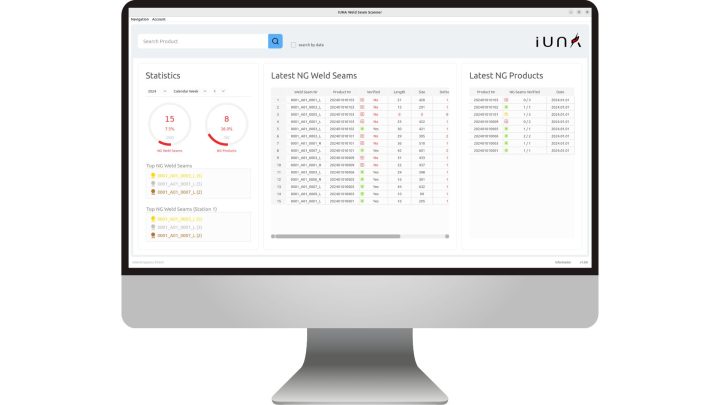

Comprehensive Statistics and Reporting

The IUNA Weld Seam Scanner provides detailed statistics and reports on your weld quality. Our intuitive dashboard gives you full transparency about your quality level, allowing you to:

- Track defect rates over time

- Identify recurring issues and their causes

- Generate detailed reports for quality management

- Export data for further analysis and documentation

The four steps to autonomous inspection

Our proven implementation process ensures a smooth integration of the IUNA Weld Seam Scanner into your production

Evaluation of Use Case

Contact us. Together, we will check your use case and the implementation options. After that we will select the required hardware components.

System installation

We integrate the camera, light module and AI box into your production process and install our AI vision software.

Labeling

The first image data is used to teach the AI inspection software. Even a small amount of images is sufficient for this.

Autonomous inspection

From now on, the IUNA Weld Seam Scanner takes over your inspection fully automatically. With the help of the statistics function, you get full transparency about your quality level.